Oil Water Separators

The Graymills Oil Separator is designed for the separation and removal of emulsified and free oil from water-based machine tool coolants used in CNC machining centers and lathes. It is effective for tramp oil separation in machine-tool systems using water-based synthetic and semi-synthetic coolant.

OSEP-5/5S FEATURES

The OSEP-5 uses simple, mechanical separation to achieve a very high level of oil removal. Unlike traditional oil skimmers which are very inefficient, the OSEP-5 works continuously even while the machine is in operation.

Easy to install and requiring low maintenance, the OSEP-5 is economical to operate, has no moving parts and requires no separate power source when installed on a recirculating system. The system extends solution life, returning virtually oil-free fluid back to the coolant sump typically reducing oil to parts per million. Its large capacity chamber can handle large sumps with ease and can even be used with centralized coolant systems holding hundreds of gallons of coolant.

It will extend the life and quality of your coolant, prevent rancidity from anaerobic bacterial growth and is a cost effective addition for any machine shop or production facility. Available in mild steel (OSEP-5) or stainless steel (OSEP-5S) the system is built to last with construction of heavy gauge steel that is MIG welded and leak tested.

|

OSEP-5/5S ORDER INFORMATION |

|

|

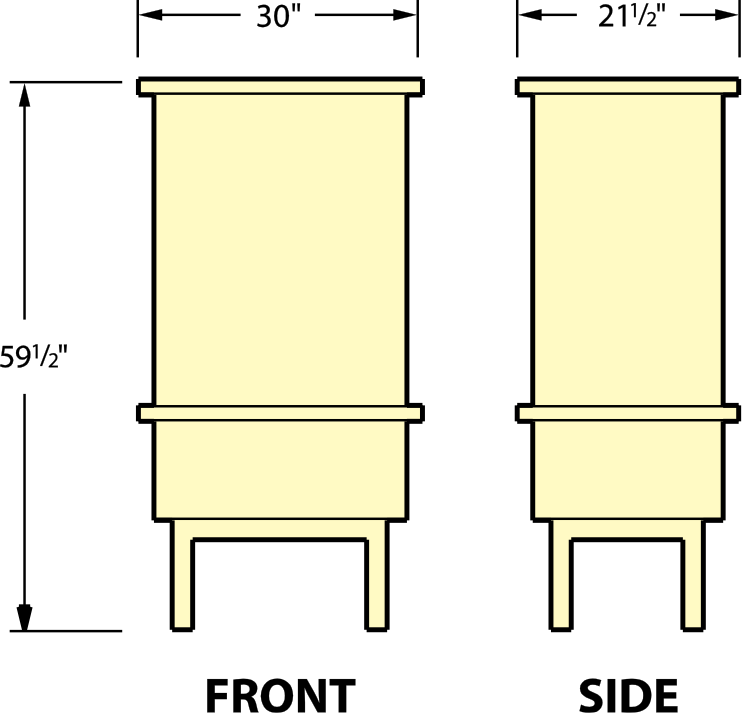

DIMENSIONS |

30” W x 21-1/2” D x 59-1/2” H |

|

CAPACITY |

120 Gallons |

|

MAX FLOW RATE |

5 GPM |

|

Notes: The oil separator is intended for water-based solutions and will not function with solvent-based or chemically emulsified fluids. Systems that do not have a recirculation pump require the separator to be equipped with its own pump. Consult factory for details. |

|

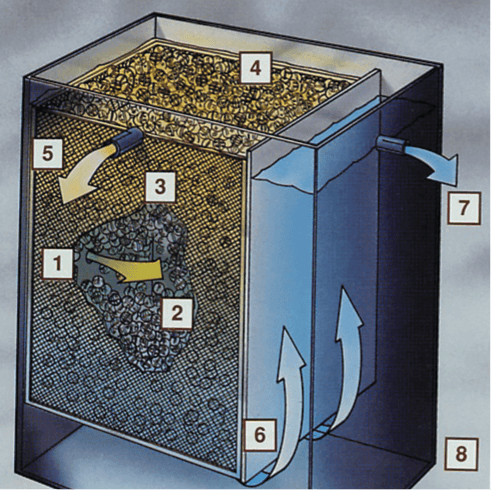

HIGHLY EFFICIENT OIL REMOVAL

- Adjustable inlet valve controls flow at five GPM to assure sufficient separation time.

- Oily solution enters larger separator chamber.

- Emulsified oil adheres to polypropylene spheres which are non-wearing and require no replacement.

- Formed droplets separate and rise to the surface to form an oil layer.

- Oil layer gravity feeds to recovery container for proper disposal, reuse or reclamation.

- Separated oil-free coolant fluid passes under baffle to second chamber.

- Virtually oil-free coolant flows back to principle reservoir.

- Bottom drain facilitates clean-out when required.