Industrial Magnetic Separation Systems

These durable, hard-working, automatic systems are designed to keep your cutting, grinding, drilling, and milling machinery operating at peak performance while keeping the coolant free of swarf, dirt, chips, grit, and other machining by-products. By filtering out harmful contaminants, coolant life is greatly extended saving both coolant replacement and labor change-out costs.

Click HERE for our Build-A-System Brochure!

The Magnetic Separator may be added to the Bed Filter Tank System for multi-layer protection or used alone where there is ferrous metal contamination. The Magnetic Separator removes ferrous metal debris from the sediment permitting simpler disposal of filter media.

- Simple flow-through design easily retrofits to existing systems.

- No filter media required so operating cost is low.

Sizes up to 100gpm are available. Consult factory for details.

|

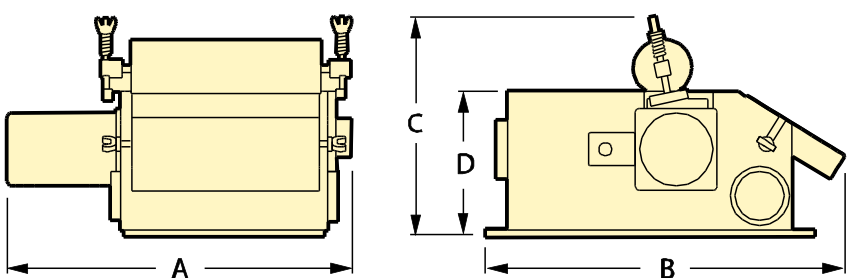

Magnetic Separator |

MS40 |

MS80 |

MS120 |

MS160 |

|

Width (A) |

13-5/8” |

17-1/2” |

18-5/8” |

22” |

|

Length (B) |

18-1/4” |

18-1/4” |

19” |

19” |

|

Total Height (C) |

11-7/8” |

11” |

12-3/8” |

12-3/8” |

|

Unit Height (D) |

8” |

7-1/4” |

8-5/8” |

8-5/8” |

|

Voltage (3 ph) |

230/460V |

230/460V |

230/460V |

230/460V |

|

Max Flow (GPM) |

10 |

20 |

30 |

40 |

|

Fluid Inlet / Outlets |

2” / 2" NPT |

2" / 2-1/2” NPT |

3” / 3" NPT |

3” / 3" NPT |